Become a Market Leader

in the

paint industry

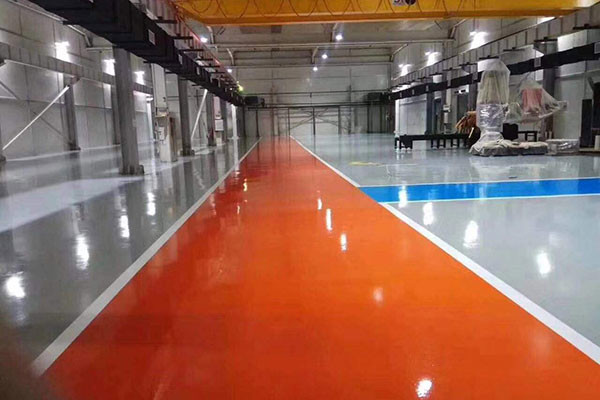

Lead the paint industry by optimizing the chemical composition of your products without going through a lengthy development process.